Product details

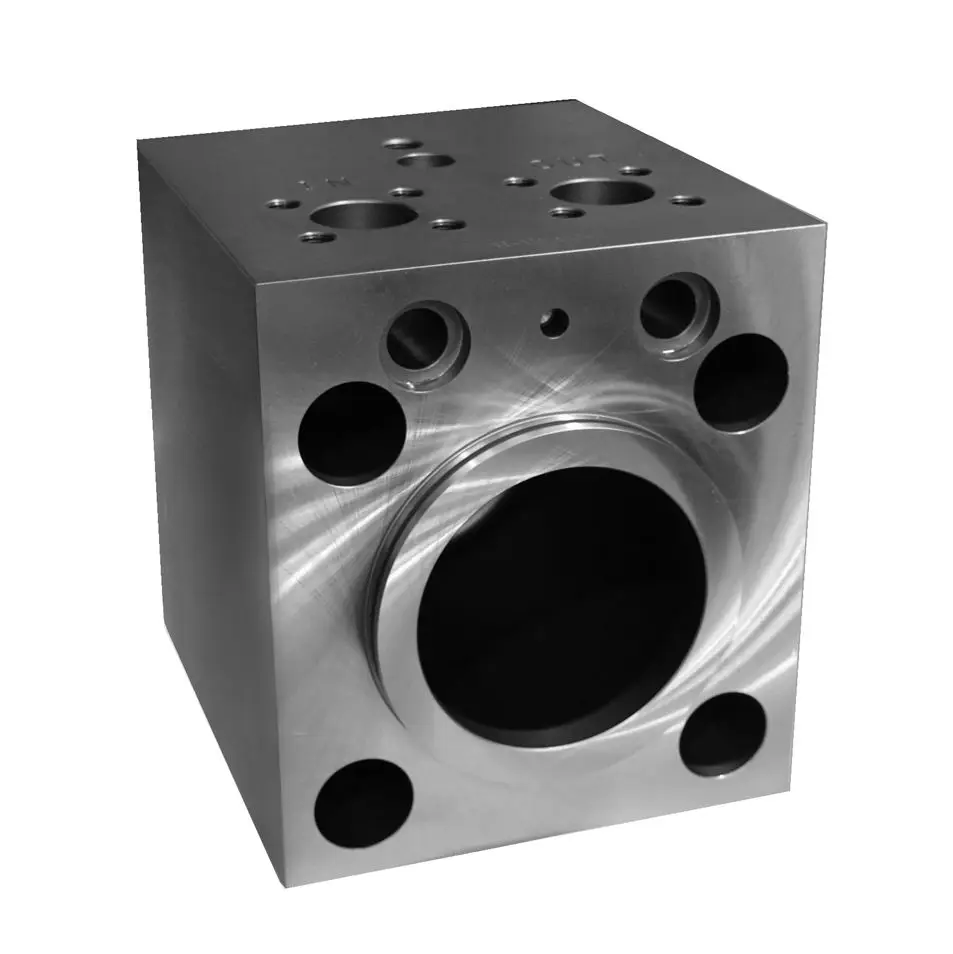

Breaker inner and outer bushing

First, the use of high-strength wear-resistant alloy material through precision numerical control processing, surface hardening heat treatment to strengthen, excellent wear resistance, can effectively withstand the crushing operation of the drill rod and cylinder high-frequency friction, to avoid premature wear caused by equipment failure, to ensure the continuous and stable operation of the breaker.

Second, accurate dimensional tolerance design, seamless fit with the crushing hammer cylinder, drill rod and other components, uniform clearance, can effectively disperse the impact force during operation, avoid parts loosening and jamming due to uneven force, and improve the overall crushing system operation stability.

Third, it has excellent impact resistance and deformation resistance. Under high-strength crushing conditions such as mines and building demolition, it can resist the instantaneous impact force of drill rod conduction, and is less prone to cracks, deformation, and other problems. Its service life is increased by more than 30% compared with ordinary bushings, reducing replacement frequency and maintenance costs.

Fourth, wide range of adaptability, can be customized according to the structural parameters of different types of breakers (such as small and medium-sized 10-ton to large 26-ton), whether domestic or imported models can be accurately matched, easy to install, no need to change the host structure, shorten the replacement operation time.

Fifth, the built-in optimized lubrication tank structure can store lubricating grease and form a long-lasting oil film, reducing dry friction between metals, and preventing debris and dust generated during crushing operations from entering the mating surface, reducing the risk of wear and reducing the frequency of lubrication maintenance.

Sixth, the use of environmentally friendly anti-rust coating treatment can effectively resist rust in humid and dusty outdoor working environments, and maintain good surface condition after long-term storage or use to avoid installation difficulties or decrease in matching accuracy due to rust.

Seventh, relying on the company's comprehensive production testing system, each batch of bushings has undergone multiple quality inspection processes such as hardness testing, size calibration, and impact testing, and the quality is controllable. For special high-strength working conditions, customized material formulas can be provided to meet personalized operation needs. Customers are welcome to inspect and verify on-site.