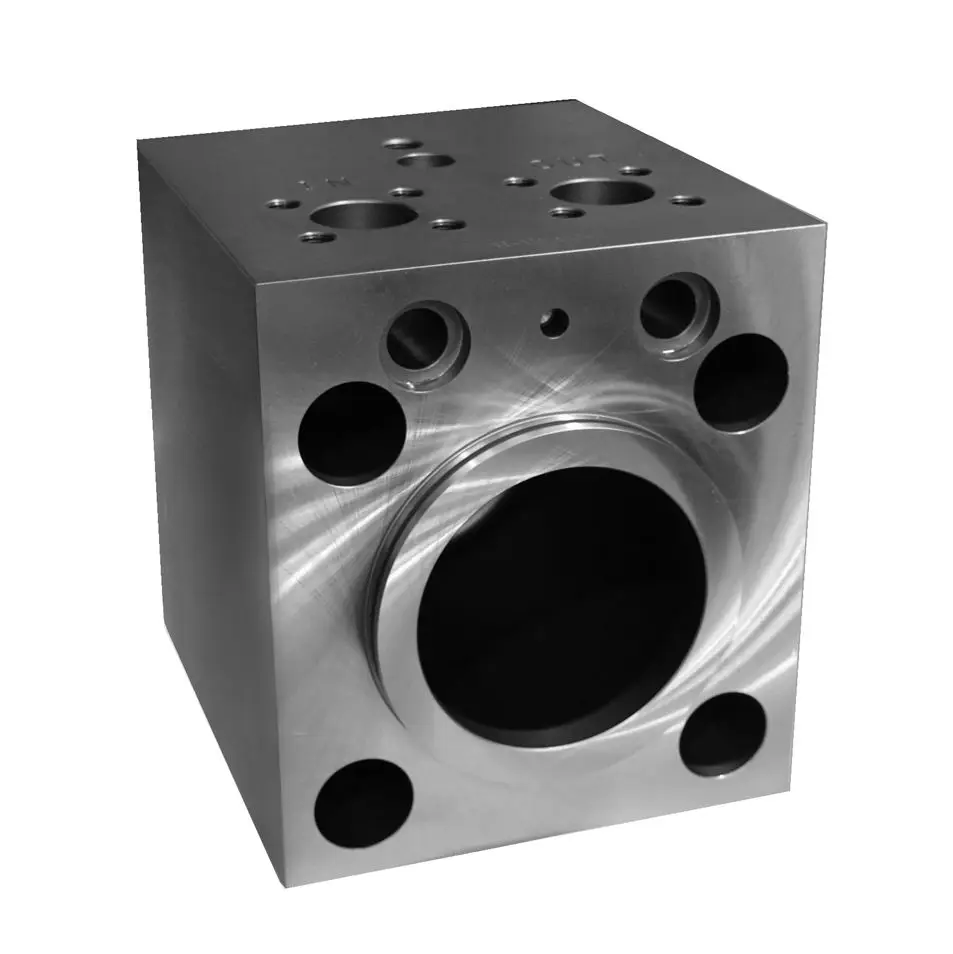

Product details

leather bowl

First, the use of high-performance elastic composite materials and precision vulcanization process, sealing rebound performance is excellent, can effectively block fluid (oil, gas, water, etc.) leakage, to ensure the operation of hydraulic and pneumatic system sealing and pressure stability.

Second, it is suitable for structural design under multiple working conditions, with excellent anti-wear and anti-extrusion performance, and can be stably sealed for a long time under complex working conditions such as dust and vibration. It is suitable for multiple scenarios such as construction machinery cylinders, automotive braking systems, and general equipment sealing cavities.

Third, relying on professional sealing technology research and development capabilities, master the core lip sealing structure process to ensure high-precision fit sealing with the cylinder block and piston, and can adapt to the sealing requirements of actuators with different cylinder diameters and different movement speeds.

Fourth, the unique medium-resistant formulation process, using special materials that are oil-resistant, acid-alkali-resistant, and aging-resistant, overcomes the drawbacks of ordinary seals that are easy to harden and fail quickly, has a long service life, reduces the time cost of equipment downtime and replacement, and improves production continuity

Fifth, for different media types (e.g. mineral oil, synthetic oil, compressed air, etc.) and temperature ranges, the material formula and structural parameters can be customized to achieve targeted and efficient sealing.

Sixth, the installation process of this leather bowl is simple, without the need for complex tooling and professional skills. In scenarios such as daily maintenance of equipment and emergency repair, it can be replaced quickly without delaying the operation of equipment.

Seventh, the lip is treated with precision modification and surface strengthening, resulting in high sealing accuracy and low friction resistance. Its sealing reliability is 2-3 times that of conventional seals. The company is equipped with professional sealing performance testing equipment (such as pressure test benches and life simulation test chambers) to ensure product quality. Users are welcome to visit the site.